To optimize inbound and outbound transport logistics, CNH chose Yard Management System

OBJECTIVE: constant control of vehicle flows, zero queues, zero waiting times, 100% efficiency 24/7.

CHALLANGE

In a warehouse, it is essential to have timely visibility over the flows of incoming and outgoing goods in order to optimize and plan production.

For CNH, the goal was to improve inbound and outbound transport logistics in real time with a digital system that is intuitive and easily accessible to all users, in order to achieve greater efficiency, control, and safety in the management and planning of vehicles and goods entering, stopping, and leaving the yards.

SOLUTION

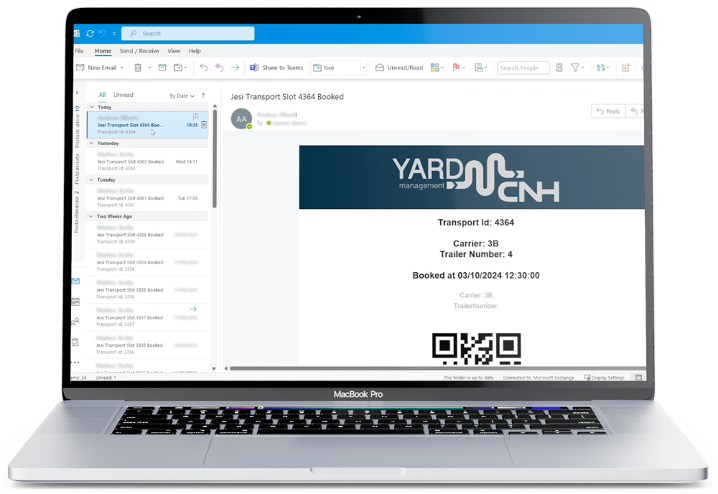

FasThink’s Yard Management System software is a management system for controlling inbound and outbound transport, ideal for production plants, distribution centers, and large warehouses, as in the case of CNH.

Developed on a web platform, YMS integrates with ERP, WMS, and MES systems and interacts with field technologies such as cameras and access control systems. Thanks to YMS, it is possible to monitor the position of vehicles in real time, optimizing loading and unloading times and routes. The system guides vehicles precisely, improving efficiency, while the management of different profiles simplifies use by users working in logistics. The YMS system automatically manages entries and exits through license plate recognition cameras, guiding drivers along an optimized route in the loading/unloading area via bidirectional communication. In addition, the software can integrate RFID systems for fast and accurate tracking, further improving operational efficiency.

RESULT

YMS has enabled digital tracking of vehicles on-site, optimizing loading and unloading windows and times, as well as vehicle routes within the area with various usage devices.

With this system, it is possible to obtain transport operation information in advance, avoiding last-minute loading area assignments and reducing waiting times for incoming vehicles. YMS also collects the data needed to measure performance, such as delivery and unloading times, allowing inefficiencies to be identified and processes optimized. In addition, all users interact through a single platform, without the need to use additional systems.

Reduction of waiting and loading/unloading times

Optimization of resource use and operating costs

Decrease in error rates and associated costs

Improvement of warehouse efficiency and reduction of storage costs

Increased visibility and real-time monitoring

Improved vehicle utilization and savings in transport costs

Reduction of total cycle times

Savings on labor costs

Sustainability

Video

Discover Yard Management System YMS

USE CASE