Pick2Light wireless & touchless system.

Pick2Light is a manual material picking system that guides the operator via a light signal to the locations from which to pick materials in a picking process.

NoIt is sure to impress and be appreciated in the world of Manufacturing and Logistics, as it allows the operator to work hands-free without the need for physical push-buttons.

Objective: zero contact, zero errors, zero wiring costs

Pick To Light systems are widely used in supermarket picking logistics in a wired version, where all light buttons are connected via a dedicated bus.

The Pick2Light system differs significantly because communication occurs wirelessly, eliminating wiring costs and increasing usage flexibility.

In the touchless version, material picking and validation occur simultaneously without the operator pressing any button to confirm the operation.

The Pick2Light system is an incredible step forward toward the future of logistics, ensuring unmatched performance in warehouse picking and kit assembly for production.

This solution is particularly suitable for picking, manufacturing, and intralogistics processes, as well as e-commerce logistics applications, where standardized timing and accuracy in material picking are essential requirements for maximum process efficiency.

The system offers remarkable flexibility because the positioning of Pick2Light buttons on each location can be modified without structural wiring changes and without the support of specialized installation technicians; therefore, this operation can also be performed by the picking operators themselves.

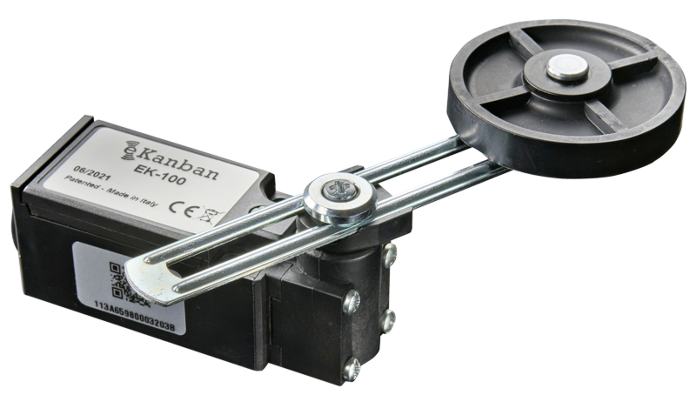

P2Light consists of a Gateway antenna capable of managing light buttons wirelessly, available in different versions to best meet usage needs, such as operator call, material call, electronic Kanban, and Put To Light and Pick To Open systems.

“Software connectors” for easy integration with existing IT systems

True to the concept of flexibility and ease of use, the available application “tools” allow easy integration of the wireless P2Light system for any type of requirement.

For Turnkey Solutions

Through the Connect Orchestrator platform, it is possible to integrate the wireless P2Light system with ERP, MES, WMS systems, manage data exchange, create product-location-button associations very quickly and easily, and monitor the system in real time using the diagnostic application according to operational needs.

Additionally, through Connect Orchestrator, it is possible to interact with optional peripherals such as e-Kanban sensors, ESL labels, as well as identification technologies such as RFID, Barcode, Mobile systems, and more, solving the challenges of the so-called “last mile.”

For System Integrator

The innovative “modular and open” design principle underlying P2Light makes this system the best “problem solver,” even for System Integrators seeking smart solutions for digital transformation in Logistics and Manufacturing.

For certified System Partners, in addition to support from qualified technicians, APIs are available for integration with their own systems.

Main Features

- Mechanical buttons

- Touchless optical detection sensor

- Bidirectional wireless communication

- High-efficiency LEDs

- Battery life up to 5 years

- Battery life monitoring

- Industrial housing

- Easy configuration and installation

- Coverage area up to 90 meters

- e-Ink graphic display

Advantages

- Touchless: no contact between operator and button panel

- Saving: elimination of wiring costs

- No Error: reduction of errors during kit preparation

- Saving: reduction of downtime caused by manual errors

- Free: hands-free picking

- Fast: simultaneous management of two or more operators

- Saving: no training required for new operators

- Smart: easy integration with ERP, MES, WMS systems

Applications

- Lean manufacturing

- Assembly lines

- Supermarket areas

- E-commerce

- Logistics and Intralogistics

- Line setup

- Operator call

- Material call

Gallery

Video

USE CASE

Check picktolight.it website