AMR

Autonomous Mobile Robot

With FasThink, a safe and reliable entry into the world of Mobile Robots.

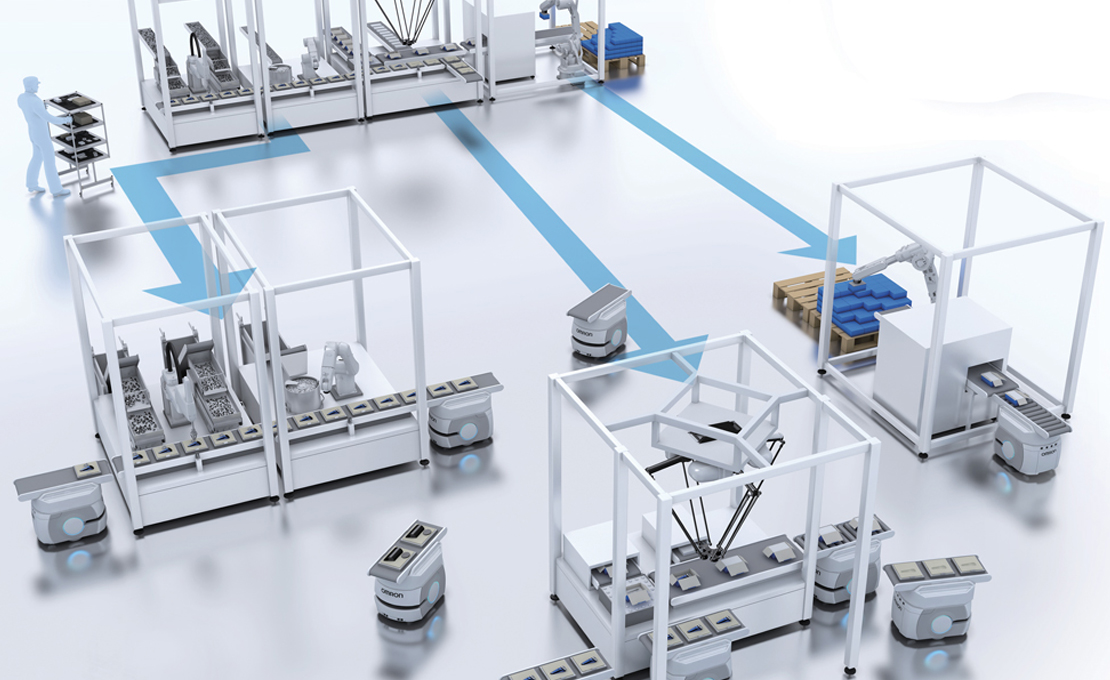

AMR Autonomous Mobile Robots, AGVs, Collaborative Robots: in the digital factory, following a now well-established evolutionary model, Mobile Robots play a key role in enabling faster and smoother interaction between logistics and production departments.

As a certified solution provider, FasThink guides and harmonizes the integration of Mobile Robots within the Industry 4.0 framework toward ERP, MES, and WMS systems. The Connect Orchestrator platform is prepared for integration modules for Mobile Robots, AGVs, and Collaborative Robots. The system allows management of different technologies, such as Pick2Light, e-Kanban, and ESL systems, which are commonly synchronized in Manufacturing & Logistics environments.

For this specific application, FasThink has chosen Autonomous Mobile Robots (AMRs) because they represent a significant step forward in optimizing production and logistics activities: when integrated with RFID systems, Pick2Light, e-Kanban sensors, and ESL, they increase productivity, eliminate errors, improve material traceability, and allow personnel to focus on more complex tasks. Unlike traditional AGVs, AMRs “navigate” using the existing facility infrastructure, without requiring costly modifications.

Designed to meet the next-generation requirements of the sector, the interaction between Connect Orchestrator AI, FasThink proprietary Pick2Light and e-Kanban systems, and AMR mobile robots opens a new frontier for SMEs, enabling modern human-machine collaboration in a safe working environment.

The latest generation of AMR Mobile Robots features vehicles specifically designed to move autonomously and reach designated targets, avoiding obstacles while simultaneously recalculating their route.

AMRs can recalculate travel paths using dedicated sensors, laser scanners, or cameras, which detect the surrounding layout and map the environment in which they operate. Thanks to sensors and digital maps managed by the MRC controller, the device can move freely. In most cases, detection of key map points is combined with robot odometry generated by wheel encoders and a set of gyroscopes and accelerometers onboard the robot.

AMRs can operate safely even around moving obstacles, such as production personnel, fostering effective human-machine collaboration.

AGV functionality is very similar to that of AMR Mobile Robots, but the way they operate is completely different. Unlike Mobile Robots, AGVs navigate using existing infrastructure, such as reflectors, magnetic strips, and more.

AGVs are widely used but require proper integration and harmonization with existing IT systems and infrastructure. In this regard, FasThink, with its proprietary Connect Orchestrator AI platform, effectively integrates and harmonizes AGV technology in Manufacturing and Logistics departments.

Gallery

Video

Want more information?

COMPANY PROFILE